Spray Arm / Wand For Electric Bidet

SZH's smart toilet control board PCBA is designed for premium electronic bidets, integrating seat heating, energy-saving algorithms, and multi-layer safety protection for enhanced user experience. With over 10 years of expertise, we provide ODM/OEM solutions for global brands, leveraging advanced R&D in precision molds and vertically integrated supply chains for fast delivery and cost efficiency. Annual production capacity exceeds 2 million units, SZH provide flexible customization, empowering clients to lead the smart bathroom market.

- SZH

- China

- Information

I. Product Overview

The Smart Toilet Spray Arm is a core component of next-generation bathroom cleaning systems, manufactured using high-strength engineering plastic molding technology. With innovative material formulations and precision structural design, it delivers optimal performance while reducing costs, making it an ideal solution that balances hygiene, safety, and cost-efficiency.

II. Core Technical Parameters

Structural Design

Spray Arm Length: 180mm ±0.5mm (customizable)

Extension Stroke: 45mm ±1mm (dual-track guidance)

Oscillation Angle: ±12° (stepper motor-driven)

Water Jet Orifices: 3×0.6mm precision array (laser-drilled)

Material Properties

Main Body: Reinforced PPSU (Polyphenylsulfone)

Temperature Resistance: -40°C to 130°C (long-term use)

Flexural Strength: ≥120MPa (ISO 178 standard)

Surface Roughness: Ra ≤0.4μm (mirror polishing)

III. Key Advantages

Hygienic Performance

✅ Seamless Design (prevents bacterial growth)

✅ Built-in UV-C LED Sterilization (auto-activates after each use)

✅ Antibacterial Masterbatch (>99% antibacterial rate, JIS Z 2801)

✅ Food-Grade Silicone Seals (FDA certified)

Functional Innovations

✅ Smart Pre-Heating (prevents cold water contact)

✅ Dual Self-Cleaning System (water rinse + UV)

✅ Anti-Clog Design (0.1mm precision filter)

✅ Low-Pressure Activation (works at 0.03MPa)

IV. Reliability Testing

Mechanical Tests

Extension Fatigue Test: 150,000 cycles (no deformation)

Torque Resistance: 2N·m

Drop Test: 1.5m height (no damage)

High-Pressure Test: 1.0MPa water impact

Environmental Tests

Damp Heat Test: 85°C/85% RH for 1,000h

Thermal Cycling: -30°C to 80°C (200 cycles)

Chemical Resistance: Bleach (84 disinfectant) immersion

V. Production Control

Manufacturing Process

? Precision Injection Molding (±0.05mm tolerance)

? Ultrasonic Welding Sealing

? Automated Optical Inspection (AOI)

? 100% Air-Tightness Testing

Quality Control

✅ Raw Material Batch Testing

✅ Process Capability Index (CPK ≥1.33)

✅ 72-Hour Aging Test Before Shipment

✅ Traceability Management System

Key Benefits

? Cost Efficiency – 40% cost reduction vs. metal spray arms while retaining 90% performance

? Durable Surface Treatment – Comparable wear resistance to metal

? Seamless Structure – Eliminates hygiene risks of traditional metal joints

? Certified Quality – NSF / CE certified, ideal for smart toilet upgrades

Custom Smart Toilet Mainboard PCBA

Modular Function Design

l Core Functions (Rapid Integration)

Heating | Cleaning | Control | Hygiene |

Seat heat | Bidet wash | Power-off flush | Nozzle clean |

Dry heat | Feminine wash | Foot-sense flush | Foam shield |

Temp adjust | Massage spray | Auto flush |

|

l Advanced Customization

- Electronic Extensions:

• IoT Control: APP/Wireless remote

• HMI: Smart display + Voice feedback

• Health: urinalysis (interface reserved)

- Mechanical Synergy:

• Auto-lid motor drive optimization

• Precision foam generator control

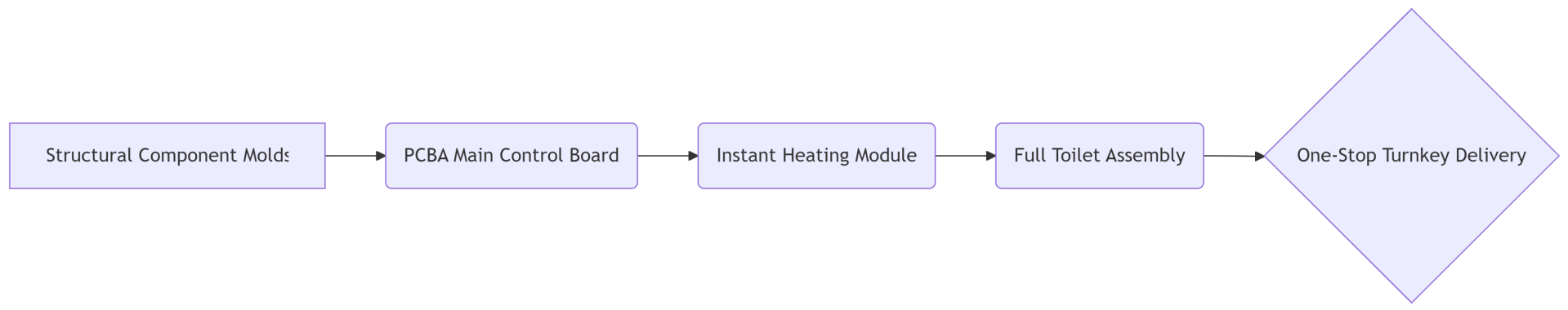

End-to-End Development

Vertical Manufacturing Advantage:

• Mold R&D: fast structural development (solves deformation/leaks)

• Electro-mechanical integration: Unified PCBA & heating module design

• Pilot to mass production: in-house SMT+assembly to ensure fast production

Competitive Benchmarking

Traditional Development Pain Points | Our Solutions | Technical Support |

slow development due to excessive feature integration | Modular design + pre-reserved interfaces | patent portfolio |

Electro-mechanical design misalignment | Parallel electro-mechanical co-development | In-house mold center + SMT production lines |

Lengthy certification cycles | Pre-validated architecture (50% test time reduction) | 10-year ODM empirical database |

Transform your smart toilet concept into a market-ready product. Welcome to contact with us today for a personalized proposal with functional prototypes, BOM optimization analysis, and turnkey delivery schedule.