Electronic Bidet Smart Toilet Control Board PCB Assembly

SZH's smart toilet control board PCBA is designed for premium electronic bidets, integrating seat heating, energy-saving algorithms, and multi-layer safety protection for enhanced user experience. With over 10 years of expertise, we provide ODM/OEM solutions for global brands, leveraging advanced R&D in precision molds and vertically integrated supply chains for fast delivery and cost efficiency. Annual production capacity exceeds 2 million units, SZH provide flexible customization, empowering clients to lead the smart bathroom market.

- SZH

- China

- Information

Custom Smart Toilet Mainboard PCBA

Modular Function Design

l Core Functions (Rapid Integration)

Heating | Cleaning | Control | Hygiene |

Seat heat | Bidet wash | Power-off flush | Nozzle clean |

Dry heat | Feminine wash | Foot-sense flush | Foam shield |

Temp adjust | Massage spray | Auto flush |

|

l Advanced Customization

- Electronic Extensions:

• IoT Control: APP/Wireless remote

• HMI: Smart display + Voice feedback

• Health: urinalysis (interface reserved)

- Mechanical Synergy:

• Auto-lid motor drive optimization

• Precision foam generator control

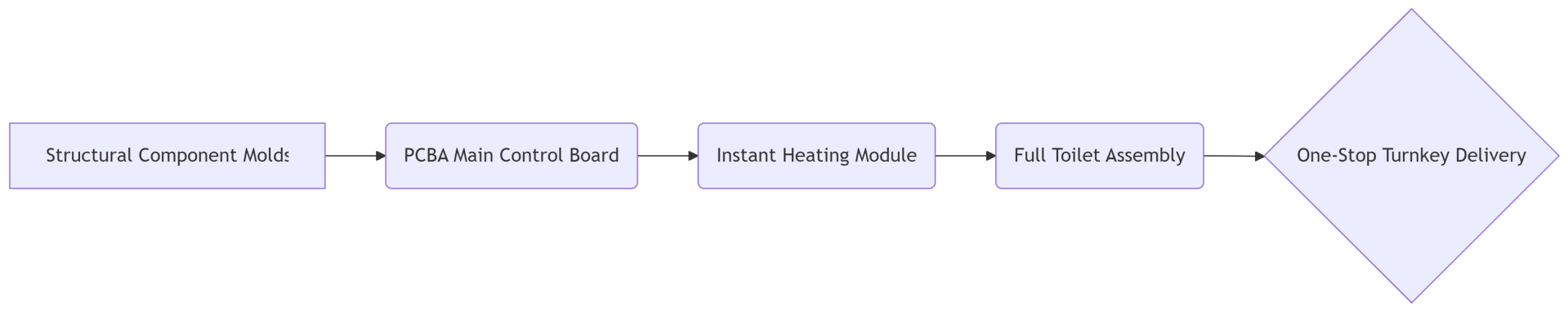

End-to-End Development

Vertical Manufacturing Advantage:

• Mold R&D: fast structural development (solves deformation/leaks)

• Electro-mechanical integration: Unified PCBA & heating module design

• Pilot to mass production: in-house SMT+assembly to ensure fast production

Competitive Benchmarking

Traditional Development Pain Points | Our Solutions | Technical Support |

Slow development due to excessive feature integration | Modular design + pre-reserved interfaces | patent portfolio |

Electro-mechanical design misalignment | Parallel electro-mechanical co-development | In-house mold center + SMT production lines |

Lengthy certification cycles | Pre-validated architecture (50% test time reduction) | 10-year ODM empirical database |

Transform your smart toilet concept into a market-ready product. Welcome to contact with us today for a personalized proposal with functional prototypes, BOM optimization analysis, and turnkey delivery schedule.

FAQ:

1. Q:What services do you offer?

A: We provide two partnership models:

ODM: Full smart toilet solutions (electronics + mechanical parts + embedded software) from concept to mass production

OEM: Custom manufacturing including PCBA, core structural components, and full assembly

Extended advantages: Collaborative development capabilities of electronics and mechanics, thoroughly addressing compatibility pain points

2. Q: What are your expertise areas in smart toilets?

A: PCBA main control boards, instant water heating technology, and electronics-mechanics integrated design.

3. Q: How do you resolve PCBA-structural part mismatches?

A: Cross-functional co-design to preempt compatibility issues and optimize structural solutions.

4. Q: How does vertical integration reduce costs?

A: Optimized BOM costs via integrated supply chain for electronics, injection molding, and hardware.

5. Q: Can you develop health monitoring features?

A: Yes, we customize main boards for advanced functions like urine analysis.

6. Q: What is your product development timeline?

A: Modular platform + proven processes cut 40% vs industry average.

7. Q: Quality control of your production lines?

A: High-precision SMT lines (ISO9001/CCC certified) with >99.2% first-pass yield.

8.Q: How do you guarantee mass production reliability?

A: 8M+ boards shipped + DFM analysis ensure zero batch failures.

9. Q: Advantages of instant heaters?

A: 3-sec heating, water-electricity isolation design, 5000+hr lifespan testing.

10. Q: How do you optimize seat heating energy consumption?

A: Proprietary algorithms reduce standby power.

11. Q: What is your minimum order quantity (MOQ)?

A: PCBA: 100 units; Full assembly: Customizable.

12. Q: Do you provide software support?

A: ODM services include embedded systems and APP connectivity solutions.

13. Q: What certifications does your factory hold?

A: ISO9001, China Compulsory Certification (CCC).

14. Q: Do you offer design optimization advice?

A: Free DFM analysis to preempt production risks.