Self-Regulating Instant Heat Module: Micro-Channel Ceramic Heater For Smart Toilets

SZH's smart toilet control board PCBA is designed for premium electronic bidets, integrating seat heating, energy-saving algorithms, and multi-layer safety protection for enhanced user experience. With over 10 years of expertise, we provide ODM/OEM solutions for global brands, leveraging advanced R&D in precision molds and vertically integrated supply chains for fast delivery and cost efficiency. Annual production capacity exceeds 2 million units, SZH provide flexible customization, empowering clients to lead the smart bathroom market.

- SZH

- China

- Information

I. Product Overview

This instant water heater is the core heating component of smart bathroom systems, utilizing next-generation flash-heating technology to deliver second-level hot water response. As illustrated, the product consists of a high-density circuit control system and a high-efficiency heating module, featuring CNI-certified industrial-grade design to provide stable and continuous hot water supply for smart toilets. Its compact structure (white housing in illustration) integrates waterway control, temperature regulation, and safety protection into a complete functional module, meeting modern bathroom systems' demands for energy efficiency, high performance, and precise temperature control.

II. Core System Analysis

Circuit Control System

Main Control Board:

32-bit microprocessor architecture

Precision SMD component layout (capacitor/resistor arrays)

Heating Module

Core Components:

316L stainless steel heating tube (inside housing)

Ceramic heat exchanger

Dual-channel water flow design

Performance Parameters:

Instant power: 3000W

Thermal conversion efficiency: ≥96%

Water temperature fluctuation: ±0.5°C

III. Key Technical Parameters

Heating Performance

Heat-up Curve:

25°C → 40°C in ≤3 sec

Max. output temperature: 55°C

Flow Characteristics:

Operating flow rate: 200–800ml/min

Minimum activation flow: 50ml/min

Electrical Safety

Insulation Properties:

Insulation resistance: ≥100MΩ

Withstand voltage: 1500V/1min

Protection System:

Leakage current cutoff: 6mA

Overload protection response: <0.1s

IV. Intelligent Control System

Temperature Management

✅ Triple-Sensor System:

Inlet temperature monitoring

Heating tube temperature tracking

Outlet temperature closed-loop feedback

✅ Control Algorithm:Adaptive PID 3.0

Dynamic power compensation

Low-temperature preheat strategy

Safety Protection

⚡ 5-Layer Protection:

Double insulation (basic + supplementary)

Water-electric separation (isolated chamber in illustration)

Fuse-based overheat protection

Flow anomaly auto-shutdown

Pressure relief valve (1.8MPa)

V. Product Advantages

Technological Innovations

? Energy Efficiency Breakthroughs:

Standby power <0.5W

35% energy savings vs. traditional heaters

? Smart Features:Usage frequency learning

Off-peak power mode

Self-diagnostic error codes

Reliability Assurance

? Durability Tests:

100,000 on/off cycles

5,000 hours continuous operation

-30°C cold-start validation

VI. Maintenance & Lifespan

⚠ Professional maintenance recommended every 12 months or 3,000 operating hours, including:

Pipe descaling

Circuit inspection

Custom Smart Toilet Mainboard PCBA

Modular Function Design

l Core Functions (Rapid Integration)

Heating | Cleaning | Control | Hygiene |

Seat heat | Bidet wash | Power-off flush | Nozzle clean |

Dry heat | Feminine wash | Foot-sense flush | Foam shield |

Temp adjust | Massage spray | Auto flush |

|

l Advanced Customization

- Electronic Extensions:

• IoT Control: APP/Wireless remote

• HMI: Smart display + Voice feedback

• Health: urinalysis (interface reserved)

- Mechanical Synergy:

• Auto-lid motor drive optimization

• Precision foam generator control

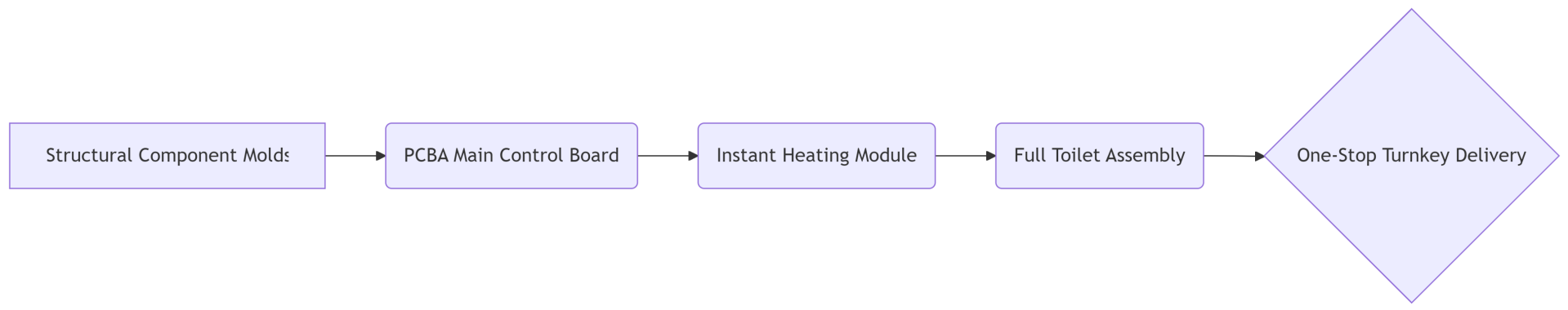

End-to-End Development

Vertical Manufacturing Advantage:

• Mold R&D: fast structural development (solves deformation/leaks)

• Electro-mechanical integration: Unified PCBA & heating module design

• Pilot to mass production: in-house SMT+assembly to ensure fast production

Competitive Benchmarking

Traditional Development Pain Points | Our Solutions | Technical Support |

slow development due to excessive feature integration | Modular design + pre-reserved interfaces | patent portfolio |

Electro-mechanical design misalignment | Parallel electro-mechanical co-development | In-house mold center + SMT production lines |

Lengthy certification cycles | Pre-validated architecture (50% test time reduction) | 10-year ODM empirical database |

Transform your smart toilet concept into a market-ready product. Welcome to contact with us today for a personalized proposal with functional prototypes, BOM optimization analysis, and turnkey delivery schedule.